Nā huahana

-

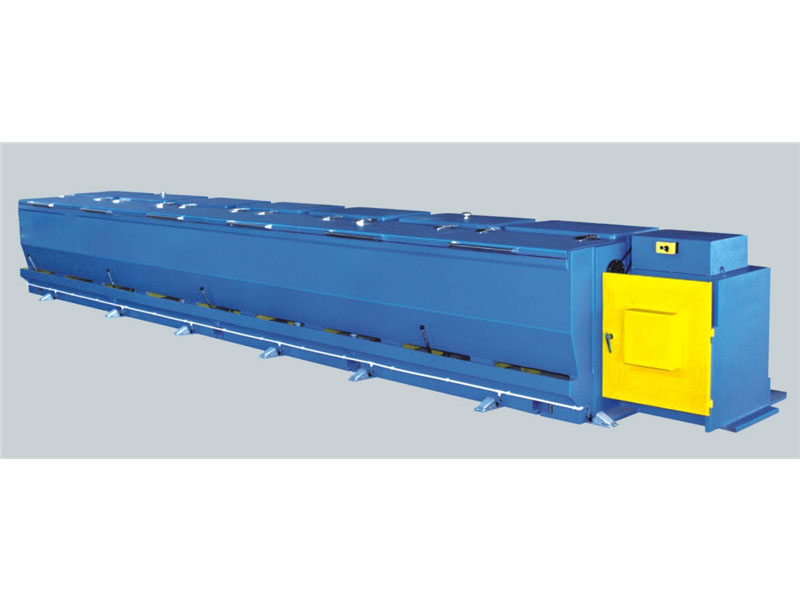

Pūnaehana hoʻolei kiʻekiʻe o Cu-OF Rod

Hoʻohana nui ʻia ka ʻōnaehana Up Casting e hana i ke koʻokoʻo keleawe manuahi oxygen kiʻekiʻe no ka uea a me nā ʻoihana kelepona. Me kekahi hoʻolālā kūikawā, hiki iā ia ke hana i kekahi mau ʻāpana keleawe no nā noi like ʻole a i ʻole kekahi mau profile e like me nā paipu a me ka pahu kaʻa.

ʻO ka ʻōnaehana me nā huaʻōlelo o ka huahana kiʻekiʻe, haʻahaʻa haʻahaʻa, hana maʻalahi, haʻahaʻa ke kumu kūʻai, maʻalahi i ka hoʻololi ʻana i ka nui o ka hana a ʻaʻohe haumia i ke kaiapuni. -

Aluminum hoʻolei ʻia a me ka laina ʻōwili—Line CCR Rod Aluminum

ʻO ka alumini hoʻolei mau a me ka laina ʻōwili e hana i ka alumini maʻemaʻe, 3000 series, 6000 series a me 8000 series aluminum alloy rods ma 9.5mm, 12mm a me 15mm diameters.

Hoʻolālā ʻia ka ʻōnaehana a hoʻolako ʻia e like me ka mea hana a me ka mana pili.

Hoʻokumu ʻia ka mea kanu i hoʻokahi pūʻulu o ka mīkini hoʻoheheʻe ʻehā huila, ka hui kaʻa, ka mea ʻulu huila, straightener a me ka multi-frequency induction heat, rolling mill, rolling mill lubrication system, rolling mill emulsion system, rod cooling system, coiler, and electrical control. ʻōnaehana. -

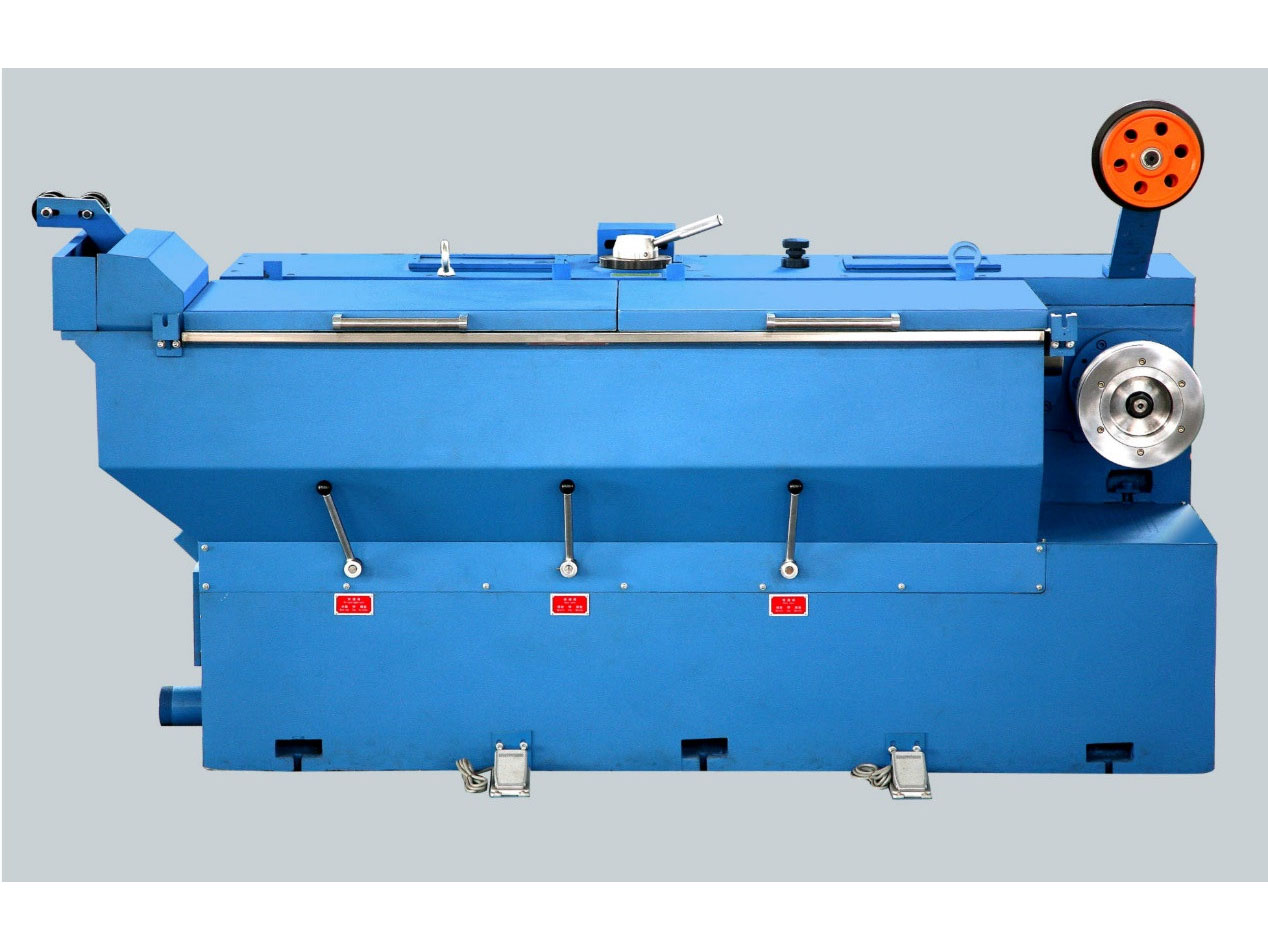

ʻO ke keleawe hoʻolei mau a me ka laina ʻōwili—laina keleawe CCR

-ʻElima huila hoʻolei mīkini me ka caster diameter o 2100mm a i ʻole 1900mm a me ka hoʻolei ʻana i ka ʻāpana ʻāpana o 2300 sqmm

-2-Roll kaʻina hana no ka ʻōwili ʻana a me 3-Roll kaʻina ʻōwili no ka ʻōwili hope loa.

-Rolling emulsion system, gear lubricating system, cooling system and other accessory equipment designed to work with the caster and rolling mill

- Hoʻoponopono ka papahana PLC i ka hana mai ka caster a hiki i ka coiler hope

- Hoʻopili ʻia ke ʻano o ka orbital; paʻa hope loa i loaʻa mai e ka mea kaomi hydraulic -

Mīkini Hoʻokaʻawale Rod me nā hoʻokele pākahi

• hoʻolālā tandem ākea

• ka hoʻokele servo a me ka ʻōnaehana hoʻomalu

• Siemens mea hoemi

• ʻōnaehana hoʻoluʻu/emulsion piha piha no ke ola lōʻihi -

Copper/ Aluminum/ Alloy Rod Break Machine

• hoʻolālā tandem ākea

• hoʻoikaika i ka hoʻoluʻu/lubrication i ka ʻaila kaʻa kaʻa o ka lawe

• helical precision mea hana e 20CrMoTi mea.

• ʻōnaehana hoʻoluʻu/emulsion piha piha no ke ola lōʻihi

• ka hoʻolālā sila ʻana me ka mīkini (ua haku ʻia me ka pā hoʻolei wai, ke apo hoʻolei ʻaila a me ka labyrinth gland) no ka mālama ʻana i ka hoʻokaʻawale ʻana o ke kaha kiʻi emulsion a me ka ʻaila. -

Kiekie-Efficiency Multi Wire Drawing Line

• hoʻolālā paʻa a me ka wāwae i hoʻemi ʻia

• hoʻoikaika i ka hoʻoluʻu/lubrication i ka ʻaila kaʻa kaʻa o ka lawe

• ka mea hoʻopololei helical a me ke kumu i hana ʻia e 8Cr2Ni4WA mea.

• ka hoʻolālā sila ʻana me ka mīkini (ua haku ʻia me ka pā hoʻolei wai, ke apo hoʻolei ʻaila a me ka labyrinth gland) no ka mālama ʻana i ka hoʻokaʻawale ʻana o ke kaha kiʻi emulsion a me ka ʻaila. -

Kiekie-Efficiency Intermediate Draw Machine

• hoʻolālā ʻano pulley cone

• hoʻoikaika i ka hoʻoluʻu/lubrication i ka ʻaila kaʻa kaʻa o ka lawe

• helical precision mea hana e 20CrMoTi mea.

• ʻōnaehana hoʻoluʻu/emulsion piha piha no ke ola lōʻihi

• ka hoʻolālā sila ʻana e mālama i ka hoʻokaʻawale ʻana o ke kaha kiʻi emulsion a me ka ʻaila. -

Kiekie-Efficiency Fine Fine Drawing Machine

Mīkini Kiʻi Uea Maikaʻi • hoʻouna ʻia e nā kāʻei pālahalaha kiʻekiʻe, haʻahaʻa haʻahaʻa. • kaa hoʻololi pālua, hoʻomalu hoʻopaʻapaʻa mau, mālama i ka ikehu • kaʻahele ma ka pōlele scre Type BD22/B16 B22 B24 Max inlet Ø [mm] 1.6 1.2 1.2 Outlet Ø range [mm] 0.15-0.6 0.1-0.32 0.08-0.32 No. 1 1 1 Ka helu o na kikoo 22/16 22 24 Max. wikiwiki [m/sec] 40 40 40 Elongation uea no ke kikoo 15%-18% 15%-18% 8%-13% Mīkini kaha kiʻi uea maikaʻi me ka Spooler kiʻekiʻe • hoʻolālā paʻa no ka mālama ʻana i ke ākea •... -

Horizontal DC Resistance Annealer

• He kūpono ka mea hoʻoheheʻe kūʻē kūʻē DC no nā mīkini hoʻohiolo koʻokoʻo a me nā mīkini kaha kiʻi waena

• ka hoʻomalu uila annealing kikohoʻe no ka uea me ka maikaʻi kūlike

• 2-3 zone annealing system

• ʻōnaehana pale naikokene a mahu paha no ka pale ʻana i ka oxidization

• hoʻolālā mīkini ergonomic a me ka mea hoʻohana no ka mālama maʻalahi -

Anealer Kū'ē DC Vertical

• ka mea hoʻopili kūʻē kūʻē DC no nā mīkini kaha kiʻi waena

• ka hoʻomalu uila annealing kikohoʻe no ka uea me ka maikaʻi kūlike

• 3-zone annealing system

• ʻōnaehana pale naikokene a mahu paha no ka pale ʻana i ka oxidization

• hoʻolālā ergonomic a me ka mea hoʻohana no ka mālama maʻalahi -

Mea Kiekie Kiekie / Barrel Coiler

• maʻalahi no ka hoʻohana ʻana i ka mīkini wāwahi koʻokoʻo a me ka laina mīkini kaha kiʻi waena

• kūpono no nā barela a me nā pahu pahu pahu

• eccentric rotating unit design for coiling wire with rosette pattern laying, and trouble-free downstream processing -

ʻOkoʻa ʻAi ʻAi ʻAi ʻAi ʻAi ʻAlua Spoole me ka Pūnaehana hoʻololi ʻakomi piha

• ka hoʻolālā spooler pālua a me ka ʻōnaehana hoʻololi spool piha no ka hana mau

• ʻōnaehana hoʻokele AC ʻekolu ʻāpana a me ke kaʻa pākahi no ka hele ʻana i ka uea

• hiki ke hoʻohana i ka spooler ʻano pintle hiki ke hoʻololi ʻia